Fabricating a splint can be time consuming and frustrating if you’ve never done it before.

When I make a capal tunnel splint, I no longer rely on patterns, but patterns can be useful at first.

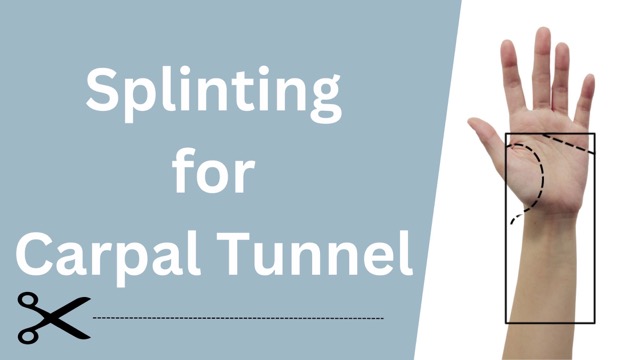

In this blog post, I’ll will go over the steps involved in fabricating a carpal tunnel splint (Wrist cockup) at home.

Before we get started, it’s important to note that a homemade plaster splint may not be as effective as a professionally made splint with thermoplastic. It’s also best to consult with a healthcare professional before attempting to treat any medical condition. With that said, let’s go over the materials and tools you will need.

Fabricating a plaster splint vs thermoplastic

The purpose of a plaster splint is act as a temporary splint until a more permanent splint is available. Plaster splints are commonly used after surgery or at a doctors office when other splints aren’t available.

A thermoplastic splint is for long term use. It’s usually for patients who need a custom splint. There’s also better than some of the prefabricated splints purchased at your local pharmacy, because they can be cleaned and they are form fitted.

Fabricating a plaster splint for carpal tunnel

Materials needed for a plaster splint

- Plaster of Paris

- Water

- Mixing bowl and spoon

- Plastic wrap

- Scissors

- Non-stick cooking spray

- Fabric or foam padding

- Velcro or other fastening material

- Measuring tape

Below is a list of the steps involved to plastering a carpal tunnel splint:

- Begin by mixing the Plaster of Paris according to the instructions on the package. You will need to add water to the plaster and stir until it reaches a smooth, creamy consistency.

- Cut a piece of plastic wrap that is large enough to cover your wrist and lower arm. Place the plastic wrap on a flat surface and spray it with non-stick cooking spray.

- Scoop a small amount of the Plaster of Paris mixture onto the center of the plastic wrap. Use the back of a spoon to spread the plaster into a thin, even layer.

- Place your wrist on top of the plaster, making sure that it is positioned in a neutral position (i.e., not bent or twisted). Wrap the plastic wrap around your wrist, securing it in place with tape or a rubber band.

- Allow the plaster to set for about 20-30 minutes, or until it is firm to the touch.

- Once the plaster has set, carefully remove the splint by cutting through the plastic wrap with scissors.

- Use a piece of fabric or foam padding to cover the rough edges of the splint and make it more comfortable to wear. Secure the padding in place with Velcro or another fastening material.

- Measure the circumference of your wrist and mark the appropriate size on the splint using a pen or marker. This will help you ensure that you are wearing the splint correctly and that it is providing the necessary support.

- To wear the splint, simply slide it onto your wrist and fasten it in place using the Velcro or other fastening material. Make sure that the splint is positioned correctly and that it is not too tight or too loose.

Fabricating a thermoplastic splint

In the video below, I go over a simple method to practice splinting without patterns. This is also discussed in my book splinting without patterns.

Here is a step-by-step guide on how to fabricate a carpal tunnel splint using thermoplastic:

Materials

- Thermoplastic sheet

- Scissors

- Ruler

- Pencil

- Heat gun

- Mold or template of the desired splint shape

- Place a light stockinette around the upper extremity to protect against heat.

- Heat the thermoplastic to 85 degrees Celsius in a splint pan with water.

- Positioning: Position the hand in a functional position (Safe position) with that wrist extended 15º

- Cut the splint in a rectangle with the width wide enough to fit the volar/dorsal aspect of the pt’s forearm. (See video)

- Cut the length from the mid forearm to the distal palmer crease

- Place the warm splint on pt’s arm carefully keeping it in place around the digits. After a few minutes remove the splint to shape.

- Measure and cut the thermoplastic sheet to the desired size and shape using the scissors and ruler (See video)

- Add velcro strapping

- Heat the thermoplastic sheet using the heat gun to soften sharp edges

- Once the thermoplastic has cooled and hardened, remove it

- Trim any excess material using scissors

- Test the fit of the splint on the intended user and make any necessary adjustments.

- Once you are satisfied with the fit, the splint is ready for use.

It’s important to use caution when heating the thermoplastic and to follow all instructions and safety precautions provided by the manufacturer. If you have any concerns about your ability to fabricate the splint safely, it is recommended that you seek the assistance of a healthcare professional.

Conclusion

That’s it! With these simple steps, you can fabricate a carpal tunnel splint at home to help alleviate the symptoms of carpal tunnel syndrome. Remember, it’s always best to consult with a healthcare professional before attempting to treat any medical condition, and a homemade splint may not be as effective as a professionally made splint. However, if you are unable to access professional treatment or if you simply want to try a DIY approach, this method can be a helpful way to provide some relief from the symptoms of carpal tunnel syndrome.

Be sure to subscribe for more OT tips and tricks!

David is the lead editor of OT Focus. He has been practicing as an Occupational Therapist since 2013. He specializes in acute care, hand therapy, and ergonomics.

![How to reduce hand swelling [Hand Therapy basics]](https://otfocus.com/wp-content/uploads/2021/03/How-to-reduce-hand-swelling-1024x576.jpg)